POST-FRAME CONSTRUCTION

CALL US TODAY AT 502.551.6190

Post-frame buildings are pre-engineered wood-frame construction systems. The walls feature laminated columns, also called posts, instead of wood studs, steel framing or concrete masonry. Post-frame buildings have evolved greatly from the early days when agricultural buyers built “pole barns” and “pole sheds.”

Post-frame structures are more quickly erected than other kinds of buildings. Because the larger posts and the interlocking frame can handle greater loads than stud-wall construction, fewer structural materials are needed – which saves on material and installation costs. Post-frame buildings transfer loads to the ground through the posts, which are typically embedded in the ground or surface-mounted to a concrete pier or masonry foundation.

Also, because posts are spaced farther apart than studs, there are fewer interruptions in insulating materials. Post-frame buildings feature an exceptionally large wall cavity for ample insulation, which allows for lowered heating and cooling costs throughout the year.

With its roots in the agricultural market, post-frame is now the construction method of choice for any number of commercial, retail, industrial, residential, religious and public building needs. Due to the nature of its design and many external façade options, post frame may be customized to provide virtually any look.

In addition to new construction, post-frame is also an effective and versatile choice for building additions and remodeling projects.

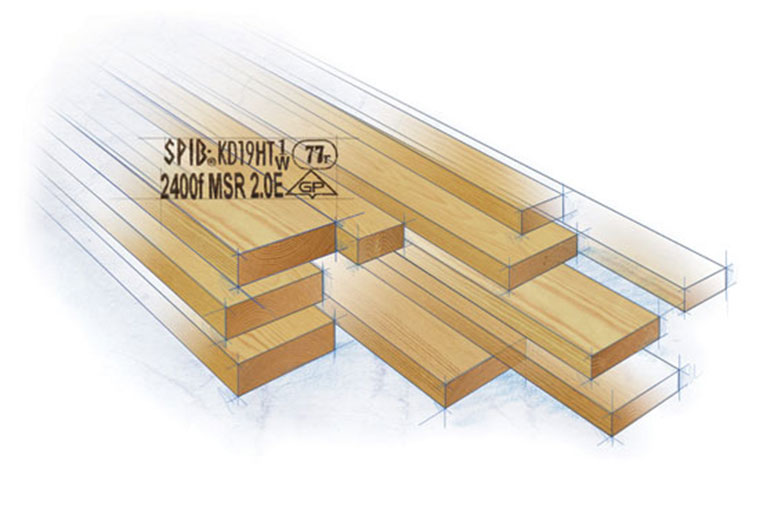

In your building’s daily clash with gravity and Mother Nature, you need all the strength you can get in your building. That’s why Wick Buildings uses only machine stress rated (MSR) and machine evaluated lumber (MEL) in your new structure.

While the competition is using #1 or #2 visual grades that don’t measure up in the strength department, with Wick you are getting lumber that is measured by a machine to meet certain minimum strength standards. And those standards provide the following strength comparison:

• Wick’s MSR 1650 2x4’s are 26% stronger for purlins (roof panel supports)

• Wick’s MSR 1650 2x6’s are 45% stronger for girts (sidewall panel supports)

• Wick’s MSR 2400 2x6 treated laminated columns are 78% stronger

You will appreciate that strength down the road with a stronger, stouter structure and less maintenance costs. We’ve all seen the effects of gravity and Mother Nature applying their brand of punishment to weaker lumber for 10 or 15 years!